OUR SERVICES

Natural Herb Extracts; Nutrition Supplement; Food Additives; OEM Series

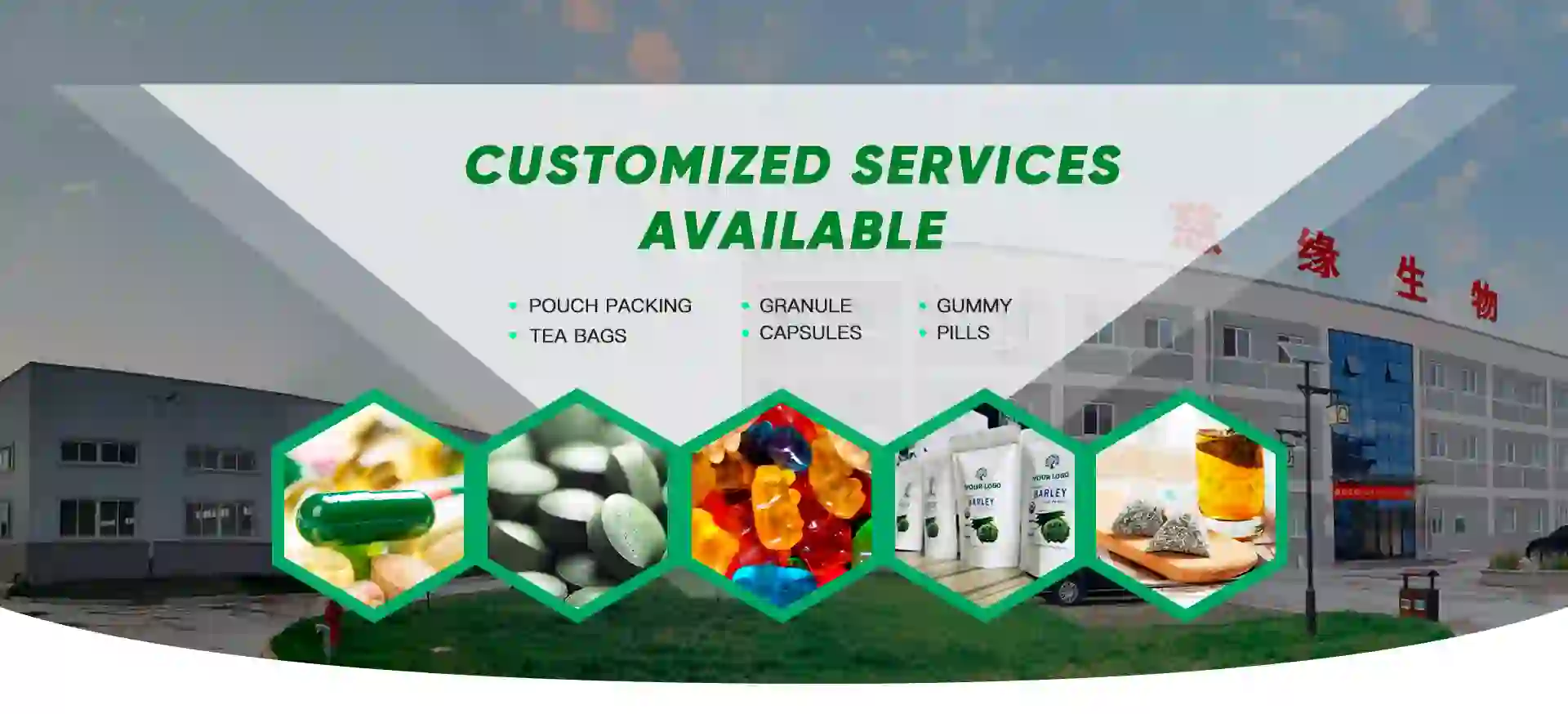

Custom Supplement Manufacturing

Use your unique recipe

Explore and optimize together

Create new and original supplements

that are unique to You

Standard production workshop

Complete machinery and equipment

Based on your needs and product planning

Guarantee your satisfactory delivery time

Strict quality inspection

Evaluate recipes before production

Test-related indicators after

Production Avoid

product risks and issues

Distinctive packaging According to your drawings or your imagination

Design and produce distinctive packaging and exclusive logos

Let your products be sold directly on the market

OUR FACTORY

Extraction;R&D;Inspection;Finished Packing

REQUESTA PRICE QUOTE

Fill out our "request a quote" form so we we can

give you a custom price quote to get started with

manufacturing your neutraceutical supplements.

OUR PROJECT PRODUCTS

THE MOST COMPETITIVE ADVANTAGE IN THE MARKET

CAPSULE MANUFACTURING

Capsules are a form of pharmaceutical preparation. Typically used to enclose solid or liquid medications in a dissolvable outer shell for easier administration. It is usually made from gelatin or plant cellulose. They can be hard or soft capsules, depending on the material used.

TABLET MANUFACTURING

Medicines are chemicals or compounds used to cure, halt, or prevent disease; ease symptoms; or help in the diagnosis of illnesses. In heather care field pill is also favored by consumers due to its ease of carrying and absorption. People use powders of natural plant ingredients and make them into pills after dry or wet granulation; in this way can the natural ingredients of plants be ensured to the greatest extent to protect our health.

SOFT CANDY MANUFACTURING

Fruit gummy candy is a candy with high moisture content, soft, elastic and tough. There are two types: transparent and opaque. Juices with different flavors added to the juice have novel colors and unique tastes, and are deeply loved by consumers. In addition to different flavors, we can also provide consumers with products in different shapes. Heart-shaped and bear-shaped are the most popular in the market.

INDIVIDUAL PACKING

With the development of e-commerce, the demand for

brand

customization is growing day by day. In order to

provide customers with better services and help

customers better expand their markets ,we provide

customers with customized packaging services. The

packaging range covers 2g-5g independent

packaging,50g-200g customized logo packaging,ect.

Single ingredients or mixed powder

formulas can be packaged as requirement.

TEA BAG MANUFACTURING

Tea bag is a kind of finished tea. It means to put

the ground tea leaves into a small bag made of

filter paper or non-woven fabric, and connect it to

a string with a label. After brewing, you can

Conveniently remove the remaining bag from the tea

soup and discard it. As people pay attention to

health products, tea drinks with various nutritional

ingredients have

emerged. We provide customers with professional

health tea

customization services and obtain marketing

assistants for you.

OUR ADVANTAGES

The Most Competitive Advantage In The Market

Low Minimum

Order Quantity

Personalized

Formulars

Worldwide Fast

Shipping

One-Stop

Customer Service

HOW TO GETSTARTED?

Customization process

1. Requirement confirmation

Confirm requirements. We need to identify what nutritional supplements the client needs. Including ingredients, uses, specifications, quantities, etc.

2. Determine the recipe

According to customer needs or formulas provided by customers. We provide relevant advice and confirm the feasibility of the formula. Ensure the safety, effectiveness, and healthiness of products, and provide customers with professional technical support.

3. Quotation

Based on your needs, we give you a quote. And ensure that the quotation is reasonable, fair, and transparent. Let customers clarify the price system of the product.

4. Production

After the customer agrees and confirms. We start production and ensure that the production quality meets relevant standards.

5. Product testing

After production is completed, product testing is carried out. Ensure product quality and safety comply with national standards.

6. Packaging and customization

We customize the packaging of products according to customer needs and carry out packaging.

7. Delivery and after-sales

After the customer confirms the product, arrange delivery. And pay attention to after-sales service, that is, respond quickly.